LEDs have transformed the lighting industry, thanks to their remarkable efficiency and long lifespan. However, powering these innovative devices requires more than simply plugging them into an electrical outlet. They rely on a crucial component known as the LED driver.

An LED driver serves as a crucial control system responsible for delivering the precise power required for optimal operation of an LED. In analogy, if LEDs were likened to race cars, then the LED driver functions as its diligent maintenance crew, ensuring it consistently operates at peak performance.

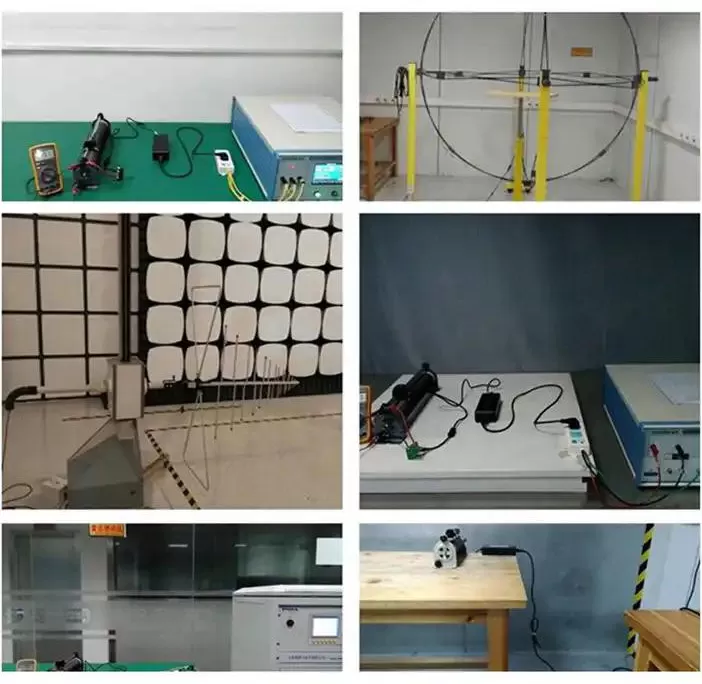

Before buying, it’s important to test whether the drive is working properly. Testing with a multimeter is an easy way to determine if an LED driver meets your needs and expectations.

Why should you test an LED driver?

Regularly testing your LED drivers is crucial in order to maximize the lifespan of your LEDs. An inefficient driver can significantly shorten their life or even render them completely unusable. To ensure optimal performance, it is recommended to use a multimeter as the preferred tool for this task. By regularly monitoring and testing your LED drivers with a multimeter, you can be confident that you are getting the most out of your LEDs and maintaining their efficiency.

Basics of a multimeter

A multimeter is a versatile electronic measuring instrument that integrates several measurement functions into a single device.

Some of its key features include:

Components: A typical multimeter consists of a rotary switch for selecting functions, a digital or analog display, and two probes.

Understand the components of LED drivers

LED drivers are electronic devices that regulate power to LED (light-emitting diode) lighting systems. They ensure that the LED receives a consistent and appropriate amount of current to operate efficiently and safely.

LED drivers typically consist of several key components that work together to provide stable, stable power to the LED lighting system, ensuring optimal performance, longevity, and energy efficiency.

Preparation is required before testing LED drivers with a multimeter

Before delving into the process of testing an LED driver with a multimeter, it’s important to make sure you’re fully prepared. Start by powering down and disconnecting the drive.

It is important to gather the tools and materials you need. This may include electrical tape, screwdrivers, wire strippers, and a multimeter.

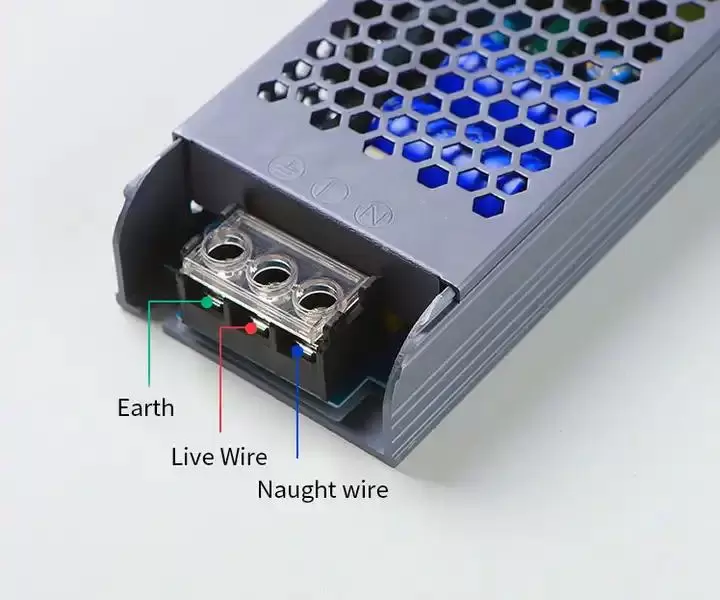

Finally, make sure you are familiar with the drive’s input and output terminals, as these are crucial during the testing process.

How to safely handle multimeters when testing LED drivers

A multimeter is an important tool for measuring voltage, current, and resistance. However, it can also be dangerous if used incorrectly, especially when testing high-voltage circuits. To avoid accidents, always wear rubber-soled shoes and work gloves when operating the multimeter.

Before connecting your multimeter to any circuit, make sure it is set to the correct range. When testing an LED driver, connect the multimeter’s probes to the driver’s input and output terminals, making sure not to touch the probes together.

Determine the type of multimeter needed to test the LED driver

A multimeter is a must-have tool when testing LED drivers. But with so many different types of multimeters on the market, how do you know which one is best for testing LED drivers?

Determining which type of multimeter you need is primarily based on the specifications of the LED driver.

By considering voltage range, current measurement capabilities, and features like auto ranging and backlit displays, you can find the right multimeter for the job and ensure accurate and reliable test results.

Test each component of the LED driver with a multimeter

When working with LED drivers, it is absolutely essential to thoroughly test every component. A multimeter is a very useful tool in this regard, as it allows you to measure every aspect of each component, from resistance to voltage, giving you a clear idea of its performance.

Disconnect the multimeter from the LED driver once all tests are complete

To ensure proper use and efficiency of your LED driver, it is important to test with a multimeter and collect accurate readings. After completing all necessary tests and recording data, it is critical to remember to disconnect the multimeter from the LED driver. Failure to do so may result in drive damage or even create a safety hazard.

Conclusion

Having a thorough understanding of LED drivers is crucial for ensuring the longevity and efficiency of LEDs. By utilizing a multimeter, it becomes effortless to assess the performance of your LED driver.

LED technology is continuously advancing, so it’s important to stay informed and ensure that your LED drivers are in optimal condition. If you’re in search of a high-quality LED driver, visit our product page and place your order today!