FACILITIES

Total Area: 10000 m2

Current Production Capacity: 200, 000 pieces

Total Area: 10000 m2

Current Production Capacity: 200, 000 pieces

The office environment at our company is excellent. The chairs are comfortable, the desk setup is ergonomic, and the view from the windows is inspiring. There is also a strong sense of community among the staff, which makes coming to work each day enjoyable.

We believe that an enjoyable and comfortable office environment is essential for employee productivity and satisfaction. That’s why we put so much effort into creating a space that our employees love coming to each day.

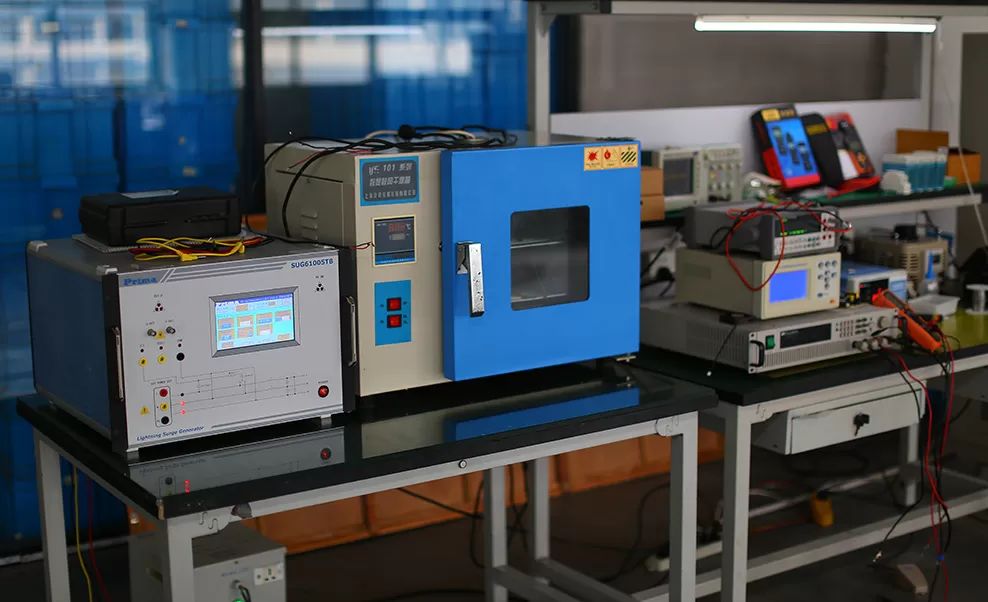

No matter what your power needs are, our excellent power supply products Laboratory can help. When you need a cost-effective, easily-installed power supply for your business or home, look no further than the variety of excellent products in our power supply laboratory. From UPS systems to Pure Sine Wave Inverters, we have the perfect power solution for your needs. All of our products are widely tested and come with a full warranty, so you can be sure you’re getting a quality product.

If you’re not sure which product is right for you, our team of experts is always available to help. We’ll work with you to find the perfect power solution for your needs, and we’ll even provide installation and support services to make sure everything goes smoothly.

The raw material storage room is an important part of our manufacturing process. It is where we keep all of the raw materials that we need for our products. The raw material storage room is temperature controlled and has a humidity control system. The raw material storage room is also equipped with a fire suppression system.

WEHO operates under the FIFO principle and is dedicated to establishing strong relationships with clients, providers, contractors, and employees. With these partnerships in mind, the company strives for mutual trust based on a genuinely positive attitude.

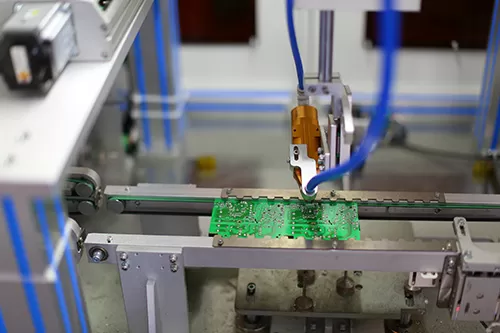

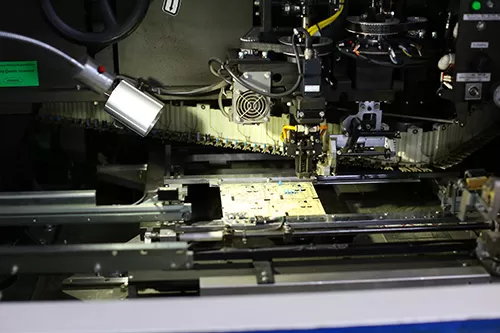

Our state-of-the-art factory is equipped with the latest machines, ensuring we can produce your project in a timely and efficient manner. Our cutting-edge panel handling system allows us to move hundreds of panels around the factory every day. Check out our gallery below to learn more about the equipment and processes that make up our factory.

This system performs automatic PCB reference point finding, error adjustments, and image alignment.

The machine is designed to efficiently insert standard electronic components into the mother seat.

This Machine is designed to be used with two-component AB glue, such as epoxy resin, PU, polyurethane, and silica gel.

It is powered by an imported motor and has steady speed control, as well as an automatic flux supply system that comes with a low liquid level alarm.

High precision, repeatable and reliable measurement can be achieved

The measurement frequency range of the device is from 9KHZ to 300MHz.

This series has outstanding load characteristics at low voltage and provides high accuracy testing solutions.

We test products such as fittings and materials under low temperatures and high temperatures to measure their performance indicators.

Offers advanced capabilities, including power test item editing and debugging, test program editing and debugging, etc.

The electronic load module is the optimal solution for replacing conventional rheostats.

This professionally designed automatic heat shrinkable film packaging and cutting machine is perfect for packaging with plastic bags and sealing them with heat shrinkable film.