Inductive proximity sensors are unsung heroes in the world of automation. These non-contact devices are fundamental to countless industrial processes, reliably detecting the presence or absence of metallic objects. But not all inductive sensors are created equal. Understanding the different inductive proximity sensor types available is crucial for selecting the right component to optimize performance, simplify integration, and ensure longevity in your specific application.

Let’s explore three primary types of inductive proximity sensors that every engineer, designer, and buyer in the automation space should be familiar with:

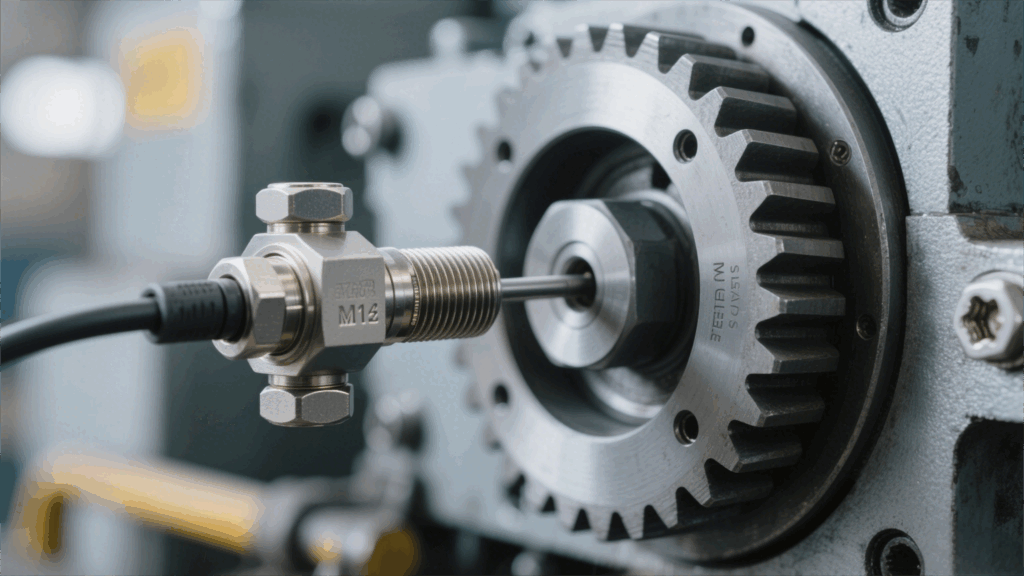

1、Cylindrical Inductive Sensors (The Workhorse)

Description: This is arguably the most common and recognizable form factor for an inductive sensor. Cylindrical sensors typically feature a threaded barrel (e.g., M5, M8, M12, M18, M30, M50 sizes) for easy mounting through drilled holes, often secured with nuts. Non-threaded smooth barrel versions also exist for clamping or press-fit applications.

Key Characteristics & Advantages:

Versatility: Their standardized form factors and wide range of sizes make them suitable for a vast array of general-purpose applications.

Sensing Range: Available in a broad spectrum of sensing distances, from a few millimeters to several centimeters, depending on the diameter and whether they are shielded or unshielded.

Mounting Options: Threaded barrels offer straightforward and adjustable mounting.

Wide Availability: Due to their popularity, they are readily available from numerous manufacturers with various electrical outputs (PNP, NPN, AC, DC, NO, NC) and connection options (cable, M8/M12 connectors).

Common Applications:

Presence/absence detection of machine parts.

Positioning and limit switching.

Counting metallic objects on conveyor belts.

Speed monitoring on rotating shafts (with toothed wheels).

Considerations:

In very confined spaces, their length or diameter can be a limiting factor.

Mounting requires a drilled hole or a suitable bracket.

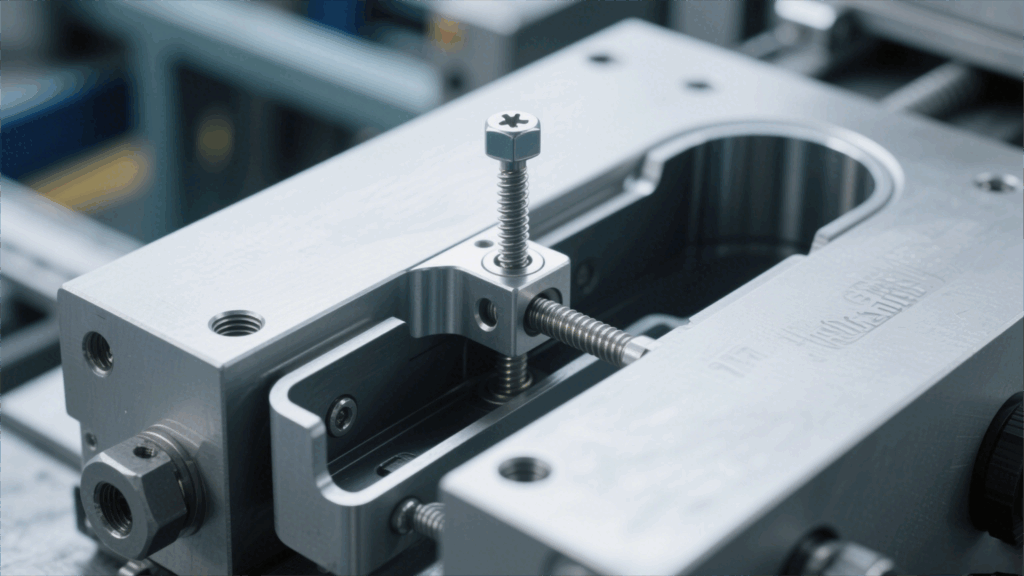

2.Rectangular / Flat Inductive Sensors (The Space Saver)

Description: As the name suggests, these inductive sensors feature a low-profile, rectangular, or “flat-pack” housing. This design makes them ideal for applications where mounting space is minimal or a more integrated look is desired.

Key Characteristics & Advantages:

Space Optimization: Their primary advantage is the ability to fit into extremely tight spaces where cylindrical sensors would be impractical (e.g., between machine components, directly on surfaces, or within shallow recesses).

Robust Mounting: Often designed for direct surface mounting, sometimes with multiple mounting holes for secure attachment. Some offer flush-mountable capabilities.

Durability: Many are available with robust metal housings (e.g., stainless steel) offering high protection against mechanical stress, oils, and coolants (high IP ratings).

Long Sensing Ranges (for their size): Advances have allowed flat sensors to achieve impressive sensing distances despite their compact form.

Smart Features: Increasingly available with IO-Link for parameterization and diagnostics.

Common Applications:

Robotic end-effectors.

Compact assembly jigs and fixtures.

Conveyor systems with minimal clearance.

Door and guard position monitoring.

Direct mounting on machine beds or frames.

Considerations:

The sensing face is typically fixed in one direction relative to the mounting surface.

While versatile, their primary strength is in space-constrained scenarios.

3.Slot (U-Shape) and Ring Inductive Sensors (The Precision Detectors)

Description: These are specialized inductive proximity sensor types designed for specific detection tasks.

Slot (U-Shape) Sensors: These have an opening or “slot” through which an object passes. The sensor detects metallic parts entering or passing through this slot.

Ring Sensors: These have a circular opening, and they detect metallic objects passing through the center of the ring.

Key Characteristics & Advantages:

Precise Detection of Small Parts: Ideal for detecting small metallic items like screws, nuts, washers, springs, or wire segments that pass through their defined sensing zone.

High Resolution: Can often detect very small changes or parts due to the concentrated sensing field within the slot or ring.

Immunity to Surrounding Metal: The design often helps to shield the active sensing zone from adjacent metal, focusing detection within the aperture.

Counting and Monitoring: Excellent for applications like parts counting, wire break detection, or verifying the presence of small metallic components in a feed tube.

Common Applications:

Slot Sensors: Detecting fins on a fan, gear teeth, control flags on moving parts, presence of parts in feed chutes.

Ring Sensors: Counting small metallic parts (e.g., nails, screws ejected from a machine), monitoring wire or small rod feed, detecting broken drill bits.

Considerations:

They are highly application-specific due to their form factor.

The size of the object to be detected must be compatible with the slot or ring aperture.

Choosing the Right Inductive Sensor Type:

Beyond these three broad categories, remember to consider other critical factors when selecting an inductive sensor:

Target Material & Size: Affects sensing distance.

Required Sensing Distance (Nominal and Operating).

Shielded vs. Unshielded: Shielded sensors allow flush mounting but typically have a shorter sensing range than unshielded sensors of the same size.

Environmental Conditions: Temperature, presence of moisture, chemicals, or potential for impact (requiring appropriate IP rating and housing material).

Electrical Output: PNP, NPN, NO (Normally Open), NC (Normally Closed), analog output.

Connectivity: Pre-cabled or connector type (M8, M12).

Switching Frequency: Important for high-speed applications.

Special Features: Such as IO-Link for advanced diagnostics and parameterization.

Understanding the fundamental inductive proximity sensor types – Cylindrical, Rectangular/Flat, and Slot/Ring – provides a solid foundation for making informed decisions. Each type offers distinct advantages suited to different application requirements. By carefully considering your application’s specific needs regarding space, mounting, the object being detected, and environmental conditions, you can select an inductive sensor that will deliver reliable, efficient, and cost-effective performance for years to come.