Inrush current, a sudden surge of current that occurs when a power supply is first turned on, is a common issue that can cause problems for both the power supply itself and the equipment it powers. This is especially true for proximity sensors, which are sensitive to voltage fluctuations and can experience damage from excessive inrush current.

This blog post will explain the reasons behind inrush current, the potential problems it can cause, and most importantly, how to effectively suppress it for your proximity sensors.

Understanding the Inrush Current Phenomenon

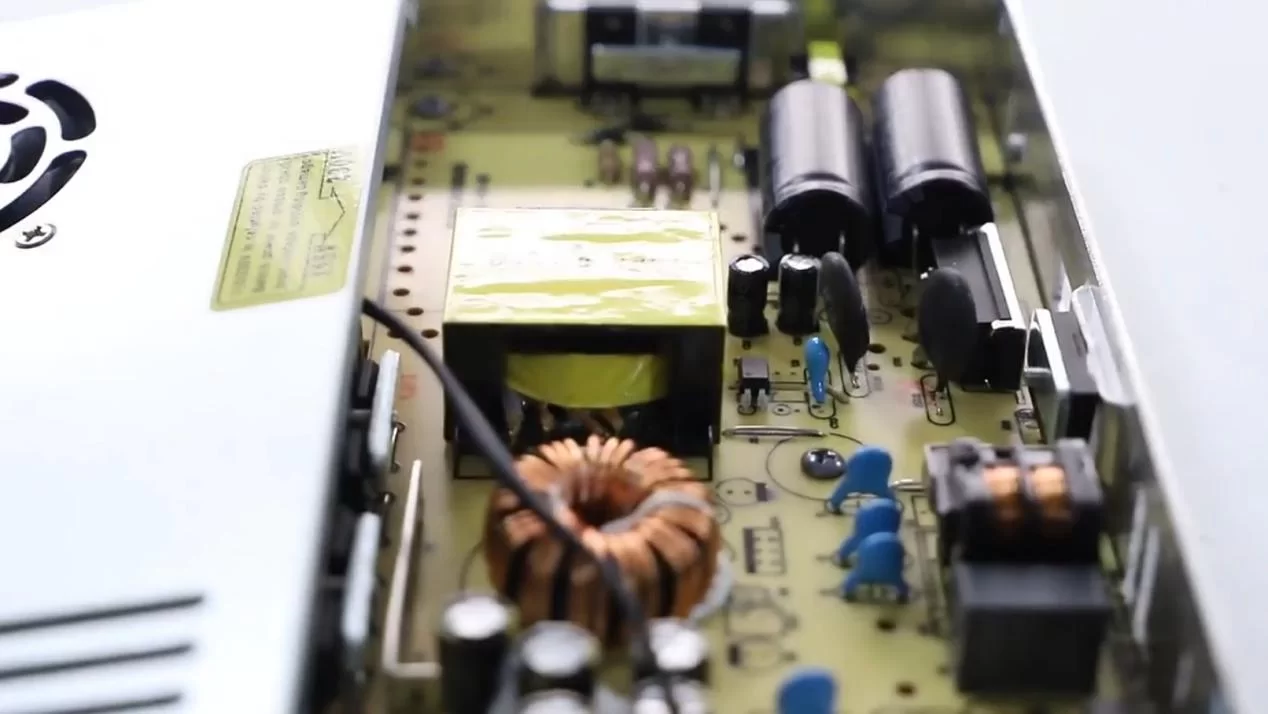

The inrush current is mainly caused by the charging of capacitors in the power supply. When the power is switched on, the capacitors, initially empty, act like short circuits, drawing a large amount of current to charge themselves. This sudden influx of current is the inrush current.

What are the Potential Problems Caused by Inrush Current?

Damage to components: Excessive inrush current can cause damage to sensitive components within the power supply, like capacitors, fuses, and even the circuit board itself.

Voltage drops: The high inrush current can cause voltage drops in the power supply, leading to malfunctioning or even complete shutdown of connected devices.

Overheating: The inrush current can cause excessive heating of the power supply and connected equipment, potentially leading to a fire hazard.

Circuit breaker tripping: The inrush current can trip circuit breakers, interrupting power to the connected devices.

Reduced lifespan: Repeated exposure to high inrush currents can shorten the lifespan of power supplies and connected devices.

Effective Techniques to Suppress Inrush Current

Fortunately, there are several methods to effectively suppress inrush current:

- Resistor-Capacitor (RC) Snubber Circuit:

A simple and common solution involves a resistor-capacitor (RC) snubber circuit connected in parallel with the power supply’s input capacitor. When the power is turned on, the resistor limits the initial current flow, while the capacitor gradually charges, reducing the inrush current over time.

- NTC Thermistor:

A Negative Temperature Coefficient (NTC) thermistor has a high resistance when cold but a low resistance when heated. When power is turned on, the thermistor initially has a high resistance, limiting the inrush current. As the thermistor heats up, its resistance decreases, allowing for normal current flow.

- Inrush Current Limiting (ICL) Device:

ICL devices are specifically designed to limit inrush current. These devices use advanced techniques, such as active current limiting and soft-start circuits, to effectively control the inrush current. They offer advantages like faster response time and lower power dissipation compared to other methods.

- Soft-Start Circuits:

Soft-start circuits gradually increase the voltage applied to the power supply over time, minimizing the inrush current. This is achieved by using a ramp function to control the voltage, preventing sudden jumps and allowing the capacitors to charge safely.

- Power Factor Correction (PFC) Circuits:

PFC circuits are primarily used to improve the power factor of the power supply, but they also have a side benefit of reducing inrush current. By shaping the input current waveform, PFC circuits reduce the peak current demand, minimizing the inrush current.

- Proper Capacitor Selection:

Choosing the appropriate capacitor for the power supply is crucial. Capacitors with low ESR (Equivalent Series Resistance) and low ESL (Equivalent Series Inductance) contribute to reducing the inrush current.

Choosing the Right Suppressor for Your Proximity Sensors:

The best inrush current suppression technique for your proximity sensors depends on several factors, including:

Power Supply Type: The type of power supply (AC/DC, switching, linear) will influence the appropriate suppression method.

Inrush Current Level: The magnitude of the inrush current will determine the required suppression level.

Cost and Complexity: Different techniques have varying cost and implementation complexity.

Space Constraints: The available space within the device can limit the size and type of suppressor circuit used.

Conclusion:

Inrush current is a significant factor to consider when designing and implementing power supplies for proximity sensors. Implementing effective inrush current suppression techniques can significantly reduce the risk of damage to components, voltage drops, and operational problems. By understanding the principles behind inrush current and employing appropriate suppression methods, you can ensure the reliable and long-lasting performance of your proximity sensors.