When specifying sensors for industrial automation, manufacturing, or any application requiring non-contact detection of metallic objects, inductive proximity sensors are often a go-to solution. They are robust, reliable, and can operate in harsh environments. However, a common point of inquiry that frequently arises is: Is an inductive proximity sensor analog or digital?

The straightforward answer is: it can be either, or in some sophisticated cases, both. Understanding the difference between analog and digital inductive sensors is crucial for buyers, as selecting the correct type directly impacts system performance, data acquisition capabilities, and overall project cost.

This post will delve deep into this question, clarifying the characteristics, applications, and benefits of both analog and digital inductive proximity sensors to help you make an informed purchasing decision.

First, A Quick Refresher: How Do Inductive Proximity Sensors Work?

Before we differentiate between analog and digital outputs, let’s briefly revisit the fundamental operating principle of an inductive proximity sensor.

The sensor generates a high-frequency electromagnetic field via a coil (inductor) in its sensing face.

When a metallic target enters this field, eddy currents are induced on the surface of the target.

These eddy currents create their own magnetic field, which opposes the sensor’s original field.

This opposition draws energy from the sensor’s oscillator circuit, causing a reduction in the oscillation amplitude.

The sensor’s internal circuitry detects this change in amplitude.

How this detected change is processed and outputted is what determines whether the sensor is classified as digital or analog.

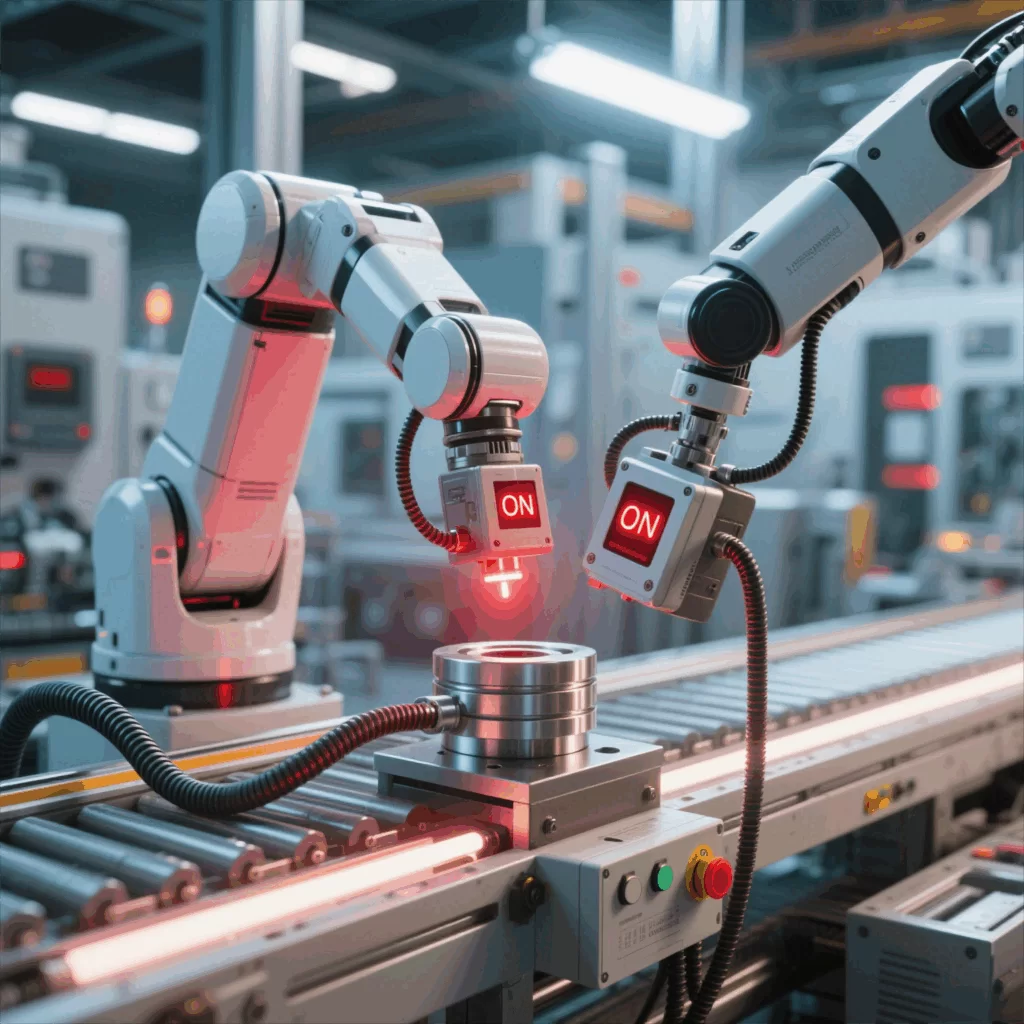

Digital Inductive Proximity Sensors: The “Yes/No” Answer

Digital inductive proximity sensors are the most common type. They provide a discrete, binary output – typically an ON or OFF state.

Operating Principle: These sensors have a pre-set trigger point or threshold. When the change in oscillation amplitude (caused by a metallic target) crosses this threshold, the output state switches. If the target is within the defined sensing range, the output is ON (or HIGH). If the target is outside this range, or no target is present, the output is OFF (or LOW).

Output Types:

NPN (Sinking): When activated, the output switches to ground (0V). The load is connected between the positive supply and the sensor’s output.

PNP (Sourcing): When activated, the output switches to the positive supply voltage (+V). The load is connected between the sensor’s output and ground.

NAMUR: A two-wire sensor that changes its current consumption to indicate presence or absence, often used in intrinsically safe applications.

Information Provided: Presence or absence of a metallic target within the nominal sensing distance. They essentially answer a “yes/no” question: “Is there a metal object here?”

Advantages:

Simplicity: Easy to understand, integrate, and troubleshoot.

Cost-Effective: Generally less expensive than their analog counterparts.

Clear Indication: Provides an unambiguous signal for PLCs and control systems.

Fast Response Times: Suitable for high-speed applications.

Typical Applications:

Presence/Absence Detection: Confirming a part is in place on an assembly line.

Counting: Counting metallic objects passing by.

Limit Switching: Detecting the end of travel for a machine component.

Positioning: Basic “in-position” checks.

Door Open/Closed Detection: Confirming the status of metallic guards or doors.

For buyers needing a straightforward, reliable method to simply detect if a metallic object is present or not, a digital inductive proximity sensor is usually the optimal and most economical choice.

Analog Inductive Proximity Sensors: The “How Far?” Answer

Analog inductive proximity sensors, conversely, offer a continuous output signal that is proportional to the distance between the sensor face and the metallic target.

Operating Principle: Instead of a simple ON/OFF switch at a threshold, the internal circuitry of an analog inductive sensor measures the degree of change in the oscillator’s amplitude (or another related parameter). This measurement is then converted into a continuously variable analog output signal, typically a voltage (e.g., 0-10V DC) or a current (e.g., 4-20mA).

Output Signal: The output signal changes linearly (or near-linearly) within the sensor’s specified operating range as the target moves closer to or further from the sensor. For example, a target at the minimum sensing distance might produce a 0V output, while a target at the maximum sensing distance within its linear range might produce a 10V output.

Information Provided: Not just presence, but also the relative distance to the metallic target within its defined measurement range. It answers the question: “How far away is the metal object?” or “What is its relative position?”

Advantages:Distance Measurement: Allows for precise measurement of target position or displacement.

Proportional Control: Can be used in feedback loops for positioning systems.

Wear Monitoring: Detecting wear on machine parts by measuring changes in gaps.

Material Thickness Variation: Can, in some specialized setups, infer material thickness variations.

Vibration Monitoring: Detecting subtle changes in position due to vibration.

Typical Applications:

Gap Measurement: Measuring the gap between a tool and a workpiece.

Positioning Tasks: Fine-tuning the position of robotic arms or machine components.

Dimensional Gauging: Checking if a part meets dimensional tolerances.

Eccentricity Monitoring: Detecting runout or wobble in rotating shafts.

Sheet Metal Thickness Monitoring: As part of a more complex system.

Level Detection (for metallic fluids or granules): Measuring the changing distance to the surface.

Buyers who need more than just a presence signal, requiring quantitative data about an object’s position or proximity, should consider analog inductive sensors.

So,Are Inductive Sensors Analog or Digital? The Key Differentiators Summarized

Feature Digital Inductive Sensor Analog Inductive Sensor

Output Signal Discrete (ON/OFF, HIGH/LOW) Continuous (e.g., 0-10V, 4-20mA)

Information Presence / Absence Distance / Proximity / Position

Operation Threshold-based switching Proportional output to distance

Complexity Simpler More complex circuitry & calibration

Cost Generally lower Generally higher

Primary Use Detection, Counting, Limit Switching Measurement, Gauging, Proportional Control

Data Type Binary Variable (quantitative)

The Rise of IO-Link: Bridging the Gap?

It’s also worth mentioning IO-Link technology. While an IO-Link sensor might have a digital (switching) output as its basic function, IO-Link communication allows it to transmit much more data, including diagnostic information, parameter settings, and sometimes even analog-like process data values. This can blur the lines, as a fundamentally digital sensor can provide more granular information, akin to an analog sensor, over the IO-Link communication channel. However, a true analog sensor will still provide a dedicated, continuous analog electrical signal.

Making the Right Choice: Guidance for Buyers

When deciding whether you need an analog or digital inductive proximity sensor, ask yourself these critical questions:

What information do I primarily need?

If it’s just “Is the object there?”: Digital is likely sufficient.

If it’s “How far away is the object?” or “What is its precise position?”: You need Analog.

What is my control system capable of handling?

Most PLCs have abundant digital inputs.

Analog inputs on PLCs are often fewer and may require specific (and sometimes more expensive) input modules. Ensure your system can accept and process 0-10V or 4-20mA signals.

What is my budget?

Digital sensors are generally more budget-friendly.

Analog sensors, due to their more complex internal electronics and calibration, tend to be more expensive.

What is the application environment and precision requirement?

For simple detection in robust environments, digital sensors excel.

For applications requiring high precision in distance measurement or continuous monitoring, analog sensors are indispensable, but ensure the sensor’s linearity and resolution meet your needs.

Do I need advanced diagnostics or parameterization?

If yes, consider sensors with IO-Link capability, whether they are fundamentally digital or offer analog data over the IO-Link protocol.

Conclusion: Both Analog and Digital Inductive Sensors Have Their Place

To directly answer the titular question: Inductive proximity sensors can be either analog or digital, depending on their design and intended application. There isn’t a “better” type; there’s only the “right” type for your specific needs.

Choose digital for cost-effective, reliable presence/absence detection and simple control tasks.

Choose analog when you require precise distance measurement, proportional control, or continuous monitoring of a metallic target’s position.

By understanding the fundamental differences in their output and the information they provide, buyers can confidently select the inductive proximity sensor that will best serve their operational requirements, ensuring efficiency, accuracy, and optimal performance in their systems. If you’re still unsure, consulting with sensor specialists or suppliers can provide tailored advice for your unique application.