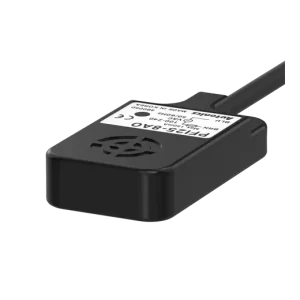

What Is a Flat Inductive Sensor?

A flat inductive sensor is a type of flat inductive proximity sensor designed to detect metallic objects without physical contact. Unlike traditional cylindrical sensors, flat inductive sensors feature a slim, rectangular profile, making them ideal for applications with limited installation space. They operate based on electromagnetic induction, generating a magnetic field that changes when a metal object enters the sensing area, thus triggering a response. These sensors are widely used in industrial automation, robotics, and machinery where precise and reliable metal detection is essential.

Flat Inductive Sensor: 6 Advantages

| Advantage | Description |

|---|---|

| Slim Profile | Compact design fits in tight spaces. |

| Durable Sensing | Non-contact operation reduces wear and extends lifespan. |

| Easy Setup | Simple installation with minimal maintenance. |

| High Precision | Accurate detection with strong resistance to interference. |

| Versatile Output | Multiple output options like PNP, NPN, and IO-Link for flexible integration. |

| Flexible Mounting | Supports both flush and non-flush installations to suit various applications. |

Slim Profile

The compact design of flat inductive sensors allows for installation in tight spaces where traditional sensors cannot fit. For example, the Baumer IF250 sensor measures only 6 mm in height yet offers a sensing distance of up to 12 mm, providing flexibility in design and integration.

Durable Sensing

Flat inductive sensors operate without physical contact, reducing wear and tear and extending their operational life. Their sealed construction protects against dust, moisture, and contaminants, ensuring reliable performance even in harsh environments.

Easy Setup

The design of flat inductive sensors simplifies installation and alignment. Their flat shape allows for straightforward mounting, and many models support plug-and-play integration, minimizing setup time and reducing maintenance requirements.

High Precision

These sensors provide accurate and repeatable detection of metal objects, making them suitable for applications requiring precise positioning and measurement. Their immunity to environmental factors like dust and light ensures consistent performance.

Versatile Output

Flat inductive sensors support various output configurations, including PNP, NPN, and IO-Link interfaces. This versatility allows seamless integration into different control systems and facilitates real-time data communication and diagnostics.

Flexible Mounting

These sensors offer multiple mounting options, such as flush and non-flush installations, to accommodate diverse application requirements. Flush mounting provides protection against mechanical damage, while non-flush mounting extends the sensing range.

Conclusion

Flat inductive sensors combine a compact form factor with robust performance, making them an excellent choice for modern industrial applications. Their non-contact operation, high precision, and flexible integration options address the challenges of space constraints and demanding environments. By incorporating flat inductive proximity sensors into your systems, you can achieve reliable metal detection and enhance overall operational efficiency.