In the ever-evolving landscape of industrial automation and machine design, efficiency, space optimization, and reliability are paramount. Engineers and procurement specialists are constantly seeking components that not only perform exceptionally but also integrate seamlessly into increasingly complex and compact systems. This is where the flat inductive proximity sensor emerges as a game-changing solution. If you’re looking to enhance your machinery’s performance, reduce downtime, and simplify installation, discover why a flat inductive sensor should be at the top of your consideration list.

What Exactly is a Flat Inductive Proximity Sensor?

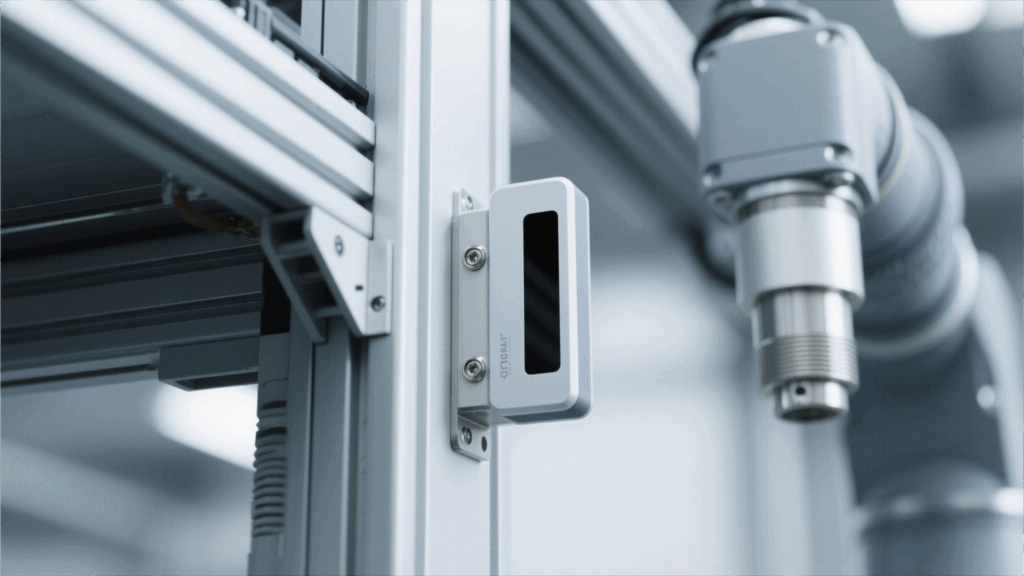

At its core, an inductive proximity sensor is a non-contact electronic device that detects the presence of metallic objects. Traditional inductive sensors often come in cylindrical housings. The flat inductive sensor, however, distinguishes itself with its low-profile, rectangular, or “flat-pack” design. This seemingly simple change in form factor unlocks a multitude of benefits, addressing many challenges faced in modern industrial environments.

Key Reasons You Should Use a Flat Inductive Sensor:

Unparalleled Space Optimization:

The Challenge: Machines are becoming more compact, and available space for components is often at a premium. Bulky sensors can create design constraints or require awkward mounting solutions.

The Flat Sensor Solution: The slim profile of a flat inductive proximity sensor allows for installation in extremely tight spaces where cylindrical sensors simply wouldn’t fit. This is ideal for applications like robotic end-effectors, compact conveyor systems, assembly jigs, and direct mounting on machine beds or frames without significant protrusion. Think about streamlined machine designs and easier integration into existing setups.

Enhanced Durability and Robustness for Harsh Environments:

The Challenge: Industrial settings can be unforgiving, with sensors exposed to oils, coolants, dust, vibrations, and potential impacts.

The Flat Sensor Solution: Many flat inductive sensors are built with robust metal housings (like the stainless steel often mentioned by manufacturers such as IFM) that offer excellent protection against mechanical stress. Their sealed design often provides high IP ratings (e.g., IP67, IP68, IP69K), ensuring reliable operation even when subjected to aggressive media or high-pressure washdowns. This translates to longer sensor life and reduced downtime due to sensor failure.

Versatile and Simplified Installation:

The Challenge: Mounting traditional sensors can sometimes require custom brackets, precise drilling, and time-consuming alignment.

The Flat Sensor Solution: Flat inductive sensors offer remarkable installation flexibility. They can often be mounted directly onto surfaces, flush-mounted, or even embedded in certain materials. Some designs, like those highlighted by IFM, offer features such as variable mounting concepts or quick-mount brackets that drastically reduce installation time and effort. This ease of installation not only saves labor costs but also minimizes machine assembly time.

Reliable Detection Performance:

The Challenge: Despite a compact design, there can be no compromise on sensing reliability and range.

The Flat Sensor Solution: Advances in technology mean that many flat inductive sensors offer impressive sensing ranges, sometimes comparable to their larger counterparts. They provide stable and precise detection of metallic targets, crucial for accurate positioning, part detection, and process control. Clear visual indicators (LEDs) for switching status and power are also standard, aiding in setup and troubleshooting.

Smart Capabilities with IO-Link Integration:

The Challenge: Modern automation demands more data, flexibility, and diagnostic capabilities from every component.

The Flat Sensor Solution: Leading-edge flat inductive sensors are increasingly available with IO-Link communication. As seen with IFM’s smart flat pack sensors, IO-Link transforms a simple sensor into an intelligent device. This allows for:

Easy Parameterization: Adjust sensing distances, switching frequencies, or output behavior (NO/NC, PNP/NPN) remotely, reducing the need for multiple sensor variants.

Advanced Diagnostics: Monitor sensor health, detect cable breaks, or identify impending issues before they cause a shutdown.

Process Data: Transmit valuable process data beyond a simple binary signal.

Identification: Store sensor-specific information for easy replacement and commissioning.

Reduced Wiring: Simplify wiring and reduce potential points of failure.

This “smart” functionality future-proofs your investment and contributes to overall equipment effectiveness (OEE).

Cost-Effectiveness Through Reduced Variants and Longevity:

The Challenge: Managing a large inventory of different sensor types can be costly and inefficient. Premature sensor failure also adds to operational costs.

The Flat Sensor Solution: The programmability offered by IO-Link in some flat inductive sensors means a single sensor model can cover a wider range of applications, reducing the number of spare parts you need to stock. Combined with their inherent robustness and long service life, the total cost of ownership (TCO) for flat inductive sensors can be significantly lower than initially perceived.

Common Applications Benefiting from Flat Inductive Sensors:

The advantages of flat inductive proximity sensors make them suitable for a vast array of industries and applications:

Factory Automation: Part detection on conveyor belts, positioning in assembly machines, presence sensing in automated guided vehicles (AGVs).

Automotive Industry: Skid detection, body shop applications, component positioning in assembly lines.

Machine Tools: Tool position detection, chuck clamping confirmation, end-of-travel sensing in limited spaces.

Material Handling: Presence detection on sorters, lifts, and transfer systems.

Packaging Machinery: Flap detection, fill level monitoring (for metallic containers), and component positioning.

Robotics: Gripper confirmation, part presence on end-of-arm tooling.

Making the Right Choice for Your Needs:

When selecting a flat inductive sensor, consider:

Sensing Range: Ensure it meets the requirements of your application.

Housing Material & IP Rating: Match it to the environmental conditions.

Output Type: PNP, NPN, or IO-Link compatibility.

Connection Type: Cable, M8, or M12 connector.

Mounting Requirements: Consider available space and preferred mounting method.

Conclusion: Embrace the Future of Sensing

Conclusion: Embrace the Future of Sensing

The flat inductive proximity sensor is more than just a component; it’s a strategic asset that can significantly enhance your machine designs and operational efficiency. Their space-saving nature, robust construction, ease of installation, reliable performance, and potential for smart functionality through IO-Link offer a compelling package for any buyer looking to optimize their sensing solutions.

By addressing common industrial challenges head-on, the flat inductive sensor provides tangible benefits in terms of reduced costs, improved uptime, and streamlined processes. It’s time to look beyond traditional form factors and explore how these innovative sensors can give your applications a competitive edge.

Interested in learning more about how flat inductive sensors can specifically benefit your application? Contact our sensor specialists today to discuss your requirements!