The question of grounding a power supply is fundamental to electrical safety and proper equipment function. While the simple answer is almost always a resounding “yes,” understanding the nuances of why grounding is necessary, the potential repercussions of improper grounding, and the best practices for establishing a robust grounding system is crucial. This blog post delves into the intricacies of power supply grounding, exploring its multifaceted benefits, the potential hazards of neglecting it, and the steps to ensure a safe and stable electrical environment.

The Importance of Grounding a Power Supply

Grounding provides a safe, low-resistance path for electrical current to flow back to the source in the event of a fault. This seemingly simple principle is the cornerstone of electrical safety and serves several critical functions:

Protection Against Electric Shock: A properly grounded power supply protects users from electric shock. If a fault occurs within the device and a live wire comes into contact with the conductive chassis, the fault current flows directly to ground, rather than through a person who might touch the chassis. This rapid flow of current triggers the circuit breaker or fuse to trip, quickly disconnecting the power and minimizing the risk of injury.

Equipment Protection: Grounding also safeguards electronic equipment from damage. Voltage surges, static discharge, and other electrical disturbances can damage sensitive components. A grounded system provides a path for these unwanted currents to dissipate harmlessly, preventing damage to the power supply and the devices connected to it.

Noise Reduction and Signal Integrity: Grounding plays a crucial role in reducing electrical noise and interference, which can disrupt the proper operation of electronic circuits. A well-grounded system provides a common reference point for electrical signals, minimizing the impact of stray electromagnetic fields and ensuring signal integrity. This is especially critical in sensitive applications like audio recording, data acquisition, and medical equipment.

Preventing Fire Hazards: In the event of a fault, a grounded system prevents the buildup of dangerous voltages on conductive surfaces. This significantly reduces the risk of fire, as sparks and overheating are minimized.

Consequences of an Ungrounded Power Supply

The consequences of operating a power supply without proper grounding can range from minor inconveniences to severe hazards, including:

Electric Shock Risk: This is the most immediate and serious danger. Contact with an ungrounded chassis that has become energized due to a fault can result in a potentially fatal electric shock.

Equipment Damage: Uncontrolled electrical surges can damage or destroy sensitive electronic components within the power supply and the connected devices.

Data Corruption: Electrical noise and interference can corrupt data being transmitted or processed by connected devices, leading to errors, data loss, and system instability.

Fire Hazard: Sparks caused by fault currents flowing through unintended paths can ignite flammable materials, potentially leading to a fire.

Increased Electromagnetic Interference (EMI): Ungrounded power supplies can act as antennas, radiating EMI and disrupting the operation of other electronic devices in the vicinity.

Best Practices for Grounding a Power Supply

Proper grounding requires attention to detail and adherence to best practices:

Three-Prong Plugs and Outlets: Always use three-prong plugs and outlets. The third prong is the grounding connection, and it should never be removed or bypassed.

Dedicated Grounding Conductor: Use a dedicated grounding conductor in the wiring. Never use the neutral wire as a ground.

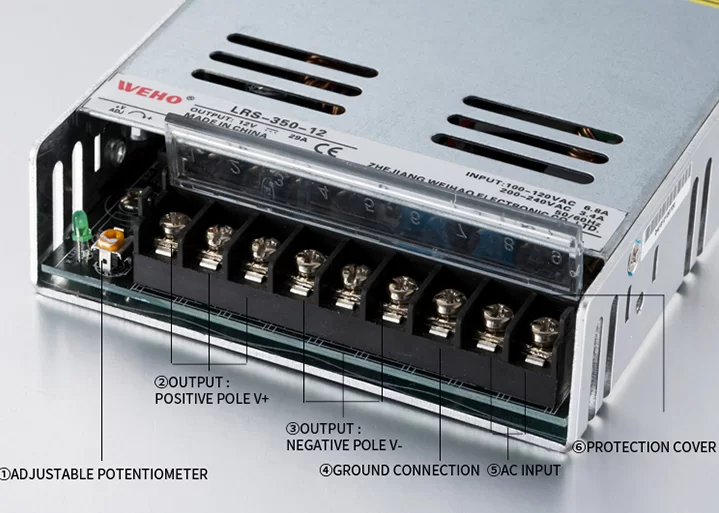

Proper Grounding Connection: Ensure a secure and low-resistance connection to a proper grounding point, such as a grounding rod or a building’s grounding system.

Grounding Integrity Testing: Regularly test the grounding system to ensure its integrity and effectiveness.

Professional Installation: For complex installations or situations involving high voltages, consult with a qualified electrician.

Adherence to Codes and Standards: Follow all relevant electrical codes and safety standards for grounding practices.

Specialized Grounding Considerations:

Certain applications may require specialized grounding considerations:

Medical Equipment: Medical equipment requires particularly stringent grounding practices to ensure patient safety.

Industrial Environments: Industrial environments often have specific grounding requirements to address the presence of heavy machinery and potentially hazardous materials.

IT Equipment: IT equipment often benefits from dedicated grounding systems to minimize noise and interference.

Conclusion:

Grounding a power supply is not merely a good idea; it’s a fundamental safety requirement and an essential element for ensuring proper equipment function. By understanding the importance of grounding, the potential dangers of neglecting it, and the best practices for achieving a robust grounding system, you can create a safe and stable electrical environment for your equipment and protect yourself from potential harm. Never underestimate the importance of this seemingly simple yet crucial aspect of electrical safety..If you Interested in Switching Power Supply and have suggestions for my Blog.Please Contact us on https://wehopower.com/ or Whatsapp:+86 18991841394 Thank you for reading this blog.